Method

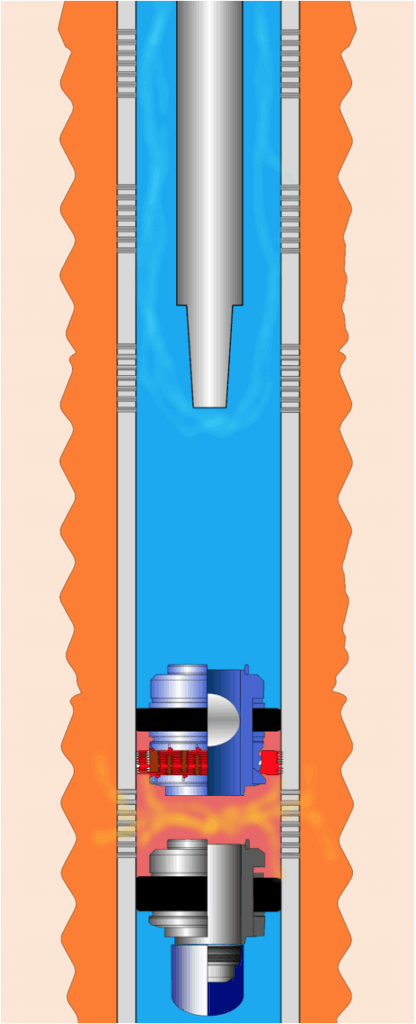

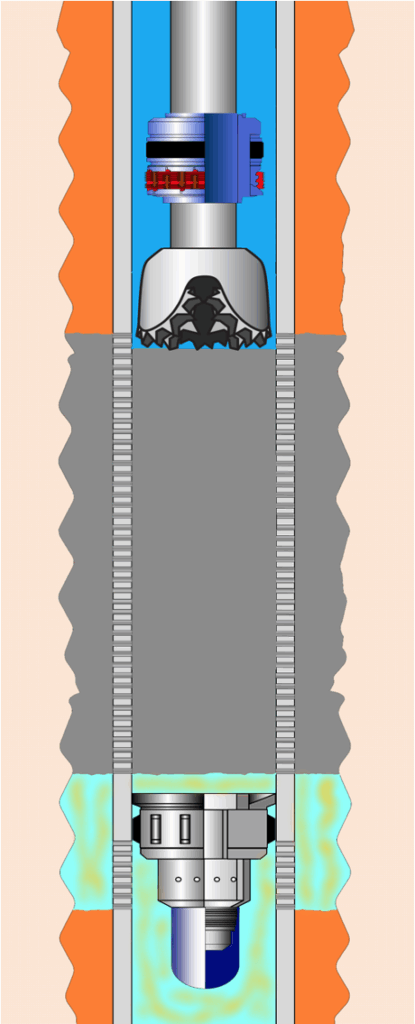

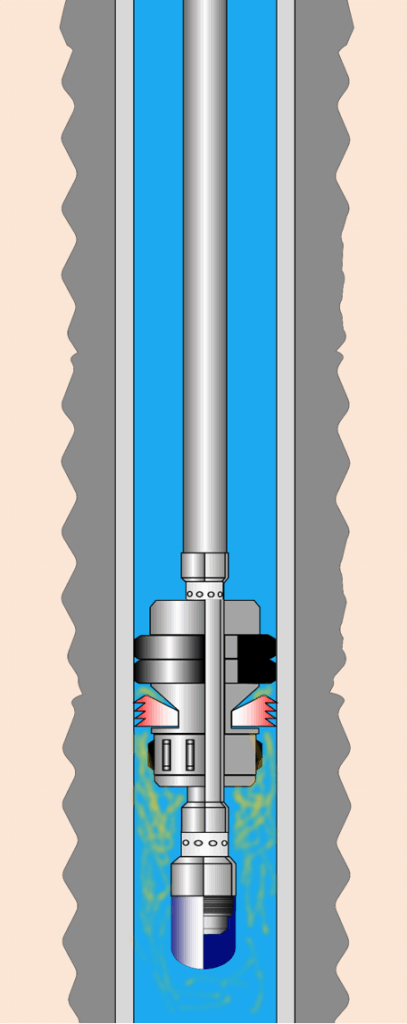

Using well known leak verification method from process industry – tracer gas injected below plug and detectors at surface to identify leaks.

- Unambiguous result – testing in right direction from the reservoir to the external environment

- Exedra’s BalderTM system typically deployed with standard brigde plug used as base for final permanent well barrier plug.

- High pressure tracer gas is released from canister with pre-programmed differential pressure over barrier to be tested.

- Two-way communication between surface and downhole.

- Extreme sensitivity, low cost & quick response, enabling new lower cost plugging solutions, e.g.shorter plug lengths.

- Dual functionality depending on application: Monitoring of tracer detection, and/or pressure response monitoring

Specifications

| Parameters | Units | Data |

|---|---|---|

| Outer Diameter | In (mm) | 5 (127) |

| Lenght (including X-over) | In (m) | 984,3 (2,5) |

| Weight | kgs | 110 |

| Connections | N/A | Standard Oilfield Connections (X-over from Stub Acme) |

| Yield tensile load | Lbf | 400.000 lbf |

| Maximim compression load | Lbf | 400.000 lbf |

| Maximum torque through tool | Lbf | 5.000 ft.lbs |

| Gas Canister volume | L | 10 |

| Maximum Operating Pressure (Gas Canister) | Psi (bar) | 7500 (517,1) |

| Maximum Pressure Rating (Tool) | Psi (bar) | 10 000 (690) |

| Maximum Operating Temperature | deg C | 130 |

| Minimum Operating/Storage Temperature | deg C | -20 |

| Pressure Sensor accuracy | deg C | +/- 7 (+/- 0,5) |

| Temperature Sensor accuracy | Psi (bar) | +/- 3 |

| Calibrated temp range | deg C | 20-130 |

| Shock and vibration | deg C | As per AWES standard |

| Tool current consumption (idle) | g | 30 |

| Tool current consumption (while operating solenoid) | mA | 630 |

| Tool Operating Voltage (single battery pack) | V | 22 |

| Normal operational time | days | 7 |

Value

Verify shorter barriers, reduce section milling lengths from established standards using Balder to mitigate risk and proof a competent barrier is established

Enables deployment of new more cost-efficient plugging solutions – e.g.short Bismuth alloy barriers

Enabling unambiguous verification of competent barrier behind casing –including dual casings

Low cost, quick response and extreme sensitive unambiguous verification of sealed permanent barrier – tested in right direction towards the external environment

Range of applications